One of the many things that can prevent your old truck from starting, or your lights from working correctly, is a corroded fuse panel. The corrosion causes high resistance in the circuits, and that means voltage loss and heat build up. Voltage loss means dim lights, flashers that click once then go dead, that kind of thing. Heat build up will melt the fuse panel, and cause the brass fuse retainer clips to lose their spring tension and no longer gripe the fuse well.

Here is what you need:

1 gallon white vinegar

1/4 cup plain table salt

1/4 cup baking soda

3 containers (like mason jars) large enough to hold the

fuse panel. I personally use powered drink mix containers (Crystal Light)

from Wal-Mart

Dremel tool with a stainless steel or brass wire wheel

or just a small brass brush

Small can of De-Oxit (Available on Amazon)

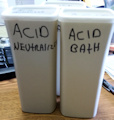

Labeled Drink Mix Containers

Mix up 1 pint of vinegar in a jar, then dissolve 1/4 cup of

table salt into it. This creates a mild acid solution, so label it Acid Bath.

Mix up one pint of water then dissolve 1/4 cup baking soda in it. This is an

acid neutralizer. Label it Acid Neutralizer.

Fill the last container with just plain tap water. This is the final rinse.

Label it Rinse Water

To clean/de-rust the entire fuse panel. First scrub the panel under hot water

with an old tooth brush and some dish soap. This will get all the dirt and grease

off of it so it does not contaminate your solutions. Rinse in plain hot water.

Now submerge the entire panel in the vinegar solution for about 10-15 minutes.

You may notice some bubbling which is normal. Remove the panel, shake off the

excess solution and examine it. If you still see rust submerge it again for

another 10 minutes. Note: This will also remove any remaining gold colored cad

plating from the steel parts!

Remove from the acid solution and rinse with hot water. Now submerge it in the Neutralizer solution for 1 minute. This neutralizes any remaining acid. Failure to neutralize will result in the acid continuing to work...

Now submerge it in plain water, or just rinse it under the tap to remove the Neutralizer solution. Note: Failure to rinse will result in a white powdery coating (the baking soda) that is hard to remove! Blow dry.

Now use a Dremel tool with a wire wheel and medium speed and go over all the

brass/copper pieces to make them shine like new!

The now cleaned steel parts will rust quickly so one thing you can do is to first install a set of old fuses. Next screw down all the wire clamp screws. Now spray the entire panel with a clear coat. The old fuses will prevent the clear coat from getting inside the fuse clips and screwing down the wire clamp screws keeps it out of those areas.

Re-install in the truck with new fuses.

To clean individual connectors and terminals on the harness just dip each one in the vinegar solution for 1-2 minutes, then 30 seconds in the neutralizer and then 30 seconds in the plain water. This cuts the oxidization from the brass terminals in the connectors. A shot of De-Oxit on each terminal will help prevent future corrosion. Since De-Oxit is VERY expensive and the sprayer it comes with is a joke, I spray the De-Oxit into a small cup or sauce container from the fast food place and use Q-Tips and tooth picks to apply the De-Oxit to each terminal. This works really well for the male terminals and ring/spade terminals. For the female terminals the tooth pick works pretty good but you can also take a loose male terminal, saturate it with De-Oxit then insert it into the female terminal. Time consuming but works!